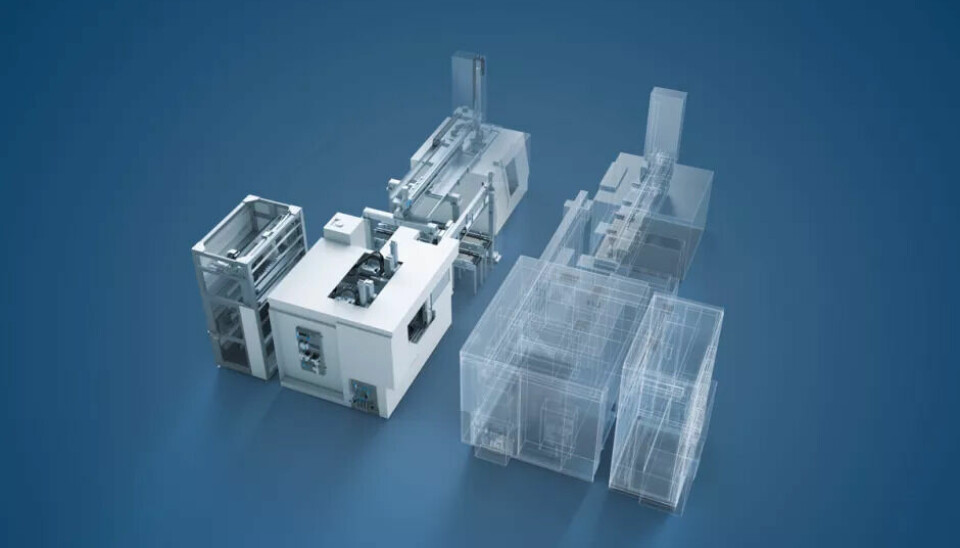

Digital replicas of automation components

Festo examines the digital twin closely

The family-owned company Festo is working intensively to equip its automation components with a digital twin. Because standardization is crucial, other German automation partners are on board.

The family-owned company from Esslingen states that they are working intensively to equip automation components with a digital twin, a digital representation in the form of administration shells. Festo is active in factory and process automation in over 35 industries. They have partnered with other German automation partners and the Industrial Digital Twin Association because standardization is what machine and plant builders expect. "Machine and plant builders will increasingly demand digital twins to develop their machines and plants faster and make fewer mistakes," explains Gerhard Borho, Chief Digital Officer at Festo. The "Digital First" principle is developing step by step: components and machines are developed virtually as far as possible before the first hardware is manufactured, which, according to Festo, extends into testing and system integration. Similar developments are seen in the company's factory planning.

Digital twins are representations with a variety of information

As the company emphasizes, digital twins of automation components are far more than just 3D models that move virtually. They are digital representations with a variety of information about the components. The Industry 4.0 machine architecture is entirely based on digital twins. Using a labeling machine, Festo has employed behavioral models of pneumatic functions for virtual commissioning. According to the company, planning and specific offer creation are already facilitated by digital twins. The advantages also include easier condition monitoring and predictive maintenance. Based on the use case, machine and plant builders should be able to experience the benefits of digital twins live in Siemens' engineering tools. The electrical and pneumatic automation products from their own repertoire and other component suppliers are used.