Cost savings through virtual planning

BMW industrializes the virtual factory

Virtual planning is a core element of BMW's iFactory, the OEM's master plan. Clever tools create digital twins of the plants. In the long term, production planning costs are expected to be significantly reduced.

The iFactory at BMW is not a specific factory or even a single, monolithic showcase plant. As Production Board Member Milan Nedeljkovic explains, it rather describes "our vision of the future and is our master plan. The focus areas are electrification, profitability, sustainability, and digitalization." Efficiency, continuous self-regulation, and complete integration are to be the focus. To make the plants smarter, effective use cases are created from innovations as part of this master plan. As the automaker currently reports, it is industrializing its Virtual Factory and thus accelerating its production planning worldwide.

The background is the numerous upcoming launches in the plants, particularly that of the completely new vehicle generation Neue Klasse, which will start in Debrecen, Hungary, and Munich. The automaker speaks of over 40 new or revised automobiles to be integrated into global production by 2027. This initially takes place virtually and then immediately stably in the plants, according to the headquarters in Munich. They also emphasize: Prospectively, the Virtual Factory of the BMW Group is expected to reduce production planning costs by up to 30 percent.

The priority is the collision check of new vehicle models

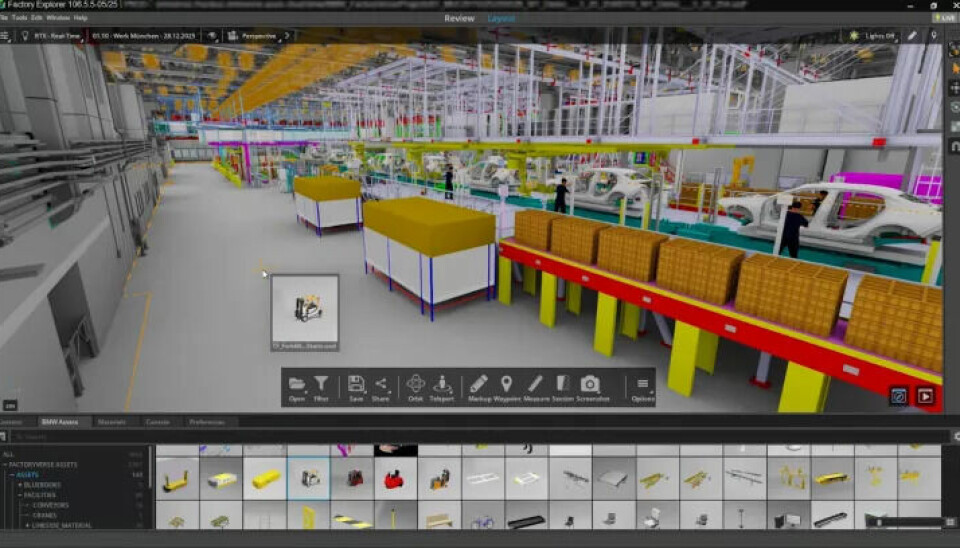

For virtual planning as a core element of the iFactory, BMW uses numerous tools and links building data, system data, logistics data, vehicle data, and 3D simulation of manual work processes. This creates digital twins of all global plants. In an industrial 3D metaverse application, simulations can be conducted in real-time, and layouts, robotics, and logistics systems can be virtually optimized. This is based on NVIDIA Omniverse. One of the essential criteria before the launch of a new model is whether it fits on the production line and does not collide with the environment at any time. According to BMW, the collision check in the virtual factory is digital, automated, and fast.

The basis for this check is design data combined with 3D scans. The movement and rotation of a vehicle through the production lines are precisely simulated, and the system automatically checks for collisions. What is now virtually simulated in just three days once took almost four weeks of real tests, according to BMW. In the past, real bodies were manually driven through the lines over several weekends to determine possible collisions. In the paint shop, the tanks for dip painting, in which the vehicle bodies are completely immersed for priming, had to be partially emptied and cleaned.

According to BMW, the use cases of the Virtual Factory can be further scaled. In addition to virtual automated collision testing, this also includes human simulation for optimizing manual production tasks or the automatic derivation of environment maps from existing 3D scans for smart transport systems.