Tin in the circular flow

Transforming waste into value in electronics

Explore how electronics firms can enhance sustainability and profitability through waste reduction and reuse strategies.

A look at the Circular Economy Act (§6) on waste hierarchy reveals that the concept of a circular economy must begin much earlier than recycling. Before waste is recycled, two other principles take precedence: prevention comes first, followed by preparation for reuse. At each of these stages, electronics companies have levers to optimize their processes.

Waste prevention and reuse as first steps

For electronics manufacturers, this means processes must be evaluated to ensure that material surpluses and waste do not occur in the first place. Even in the planning phase, production residues and rejects can be significantly reduced through design suitable for manufacturing and optimized material utilization. The overlapping of materials can also be avoided if clients and suppliers cooperate closely.

If waste cannot be completely avoided, preparation for reuse follows in the waste hierarchy - and this is significantly more energy-efficient than traditional recycling. Materials are processed so that they can be reintroduced into the production cycle without the need for complex refining processes. Dan Mutschler, CEO of MTM Ruhrzinn, describes the approach as follows: “For us, it is important to sort the waste correctly. It is necessary to think in terms of products and alloys to achieve preparation for reuse through correct batch formation.”

For electronics manufacturers, this means processes must be evaluated to prevent material surpluses and waste from occurring in the first place. Already in the planning phase, production residues and scrap can be significantly reduced through production-oriented design and optimized material utilization. Overlapping of materials can also be avoided if clients and suppliers cooperate closely.

If waste cannot be completely avoided, the next step in the waste hierarchy is preparation for reuse - and this is significantly more energy-efficient than traditional recycling. In this process, materials are prepared so they can be reintroduced into the production cycle without the need for complex refining processes. Dan Mutschler, CEO of MTM Ruhrzinn, describes the approach as follows: "For us, it is important to sort the waste correctly. It is necessary to think in terms of products and alloys to achieve preparation for reuse through correct batch formation."

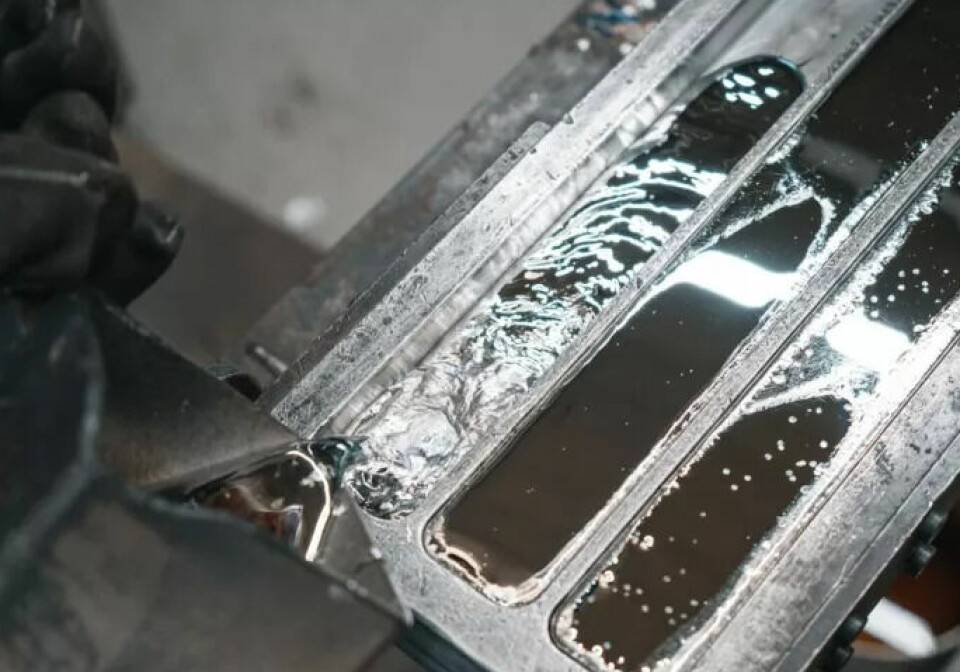

A clear example is the processing of tin dross. If it is collected in a pure form - that is, only in a specific alloy - the metallic components can be efficiently recovered. Ideally, the recovered tin can be directly reused as soldering material. A prerequisite for this is continuous quality control in the production process to ensure that the alloy composition consistently meets the standard.

Sustainability begins with sorting, utilization, and responsibility

For production waste to be truly converted into reuse, professional material flow management is necessary. A key prerequisite is the correct separation of waste by alloys, which is still not a given in many electronics manufacturing processes. Training the responsible employees plays a central role in this. Only when knowledge about material composition and purity is present can production residues be efficiently returned to the material cycle.

Not all residues can be reused easily - especially when the material flows are already mixed or involve complex assemblies. In such cases, recycling is the next logical step to still recover valuable resources. For companies like MTM Ruhrzinn, which specialize in recycling solder waste, this means: The residues are melted and broken down into their metallic components such as tin, copper, or silver through several refining stages. These are then available in pure form and can be specifically used for new alloys.

Here too, the standardization of waste separation in production is crucial. For example, unpopulated circuit boards that are sorted out due to quality defects can be collected separately from populated assemblies - an important step to make recycling processes efficient and environmentally friendly. The better the material is prepared, the higher the economic and ecological recovery value.

The cooperation between Prettl Electronics and MTM Ruhrzinn illustrates how companies can take responsibility through circular economy and simultaneously achieve measurable benefits. “We don’t just throw away complaints, but ensure that the material is reused or recycled,” emphasizes Quentin Zapf. It pays off: just last year, over 1.5 tons of waste from various Prettl locations were upgraded - resulting in a profit increase of over 20% compared to the previous disposal solution.

The environment also benefits: around 23,500 kilograms of CO₂ equivalents were saved through optimized recycling - an amount equivalent to about 16 flights between Frankfurt and New York. The savings were documented by MTM Ruhrzinn in a TÜV-certified CO₂ footprint certificate (PCF according to DIN ISO 14067:2019).

The collaboration exemplifies how ecological and economic interests can be united through smart waste strategies. Especially in an industry facing increasing resource and cost pressures, waste prevention, reuse, and recycling can become crucial levers. Those who think along the entire value chain not only reduce operating costs and the CO₂ footprint but also meet increasing regulatory requirements in the areas of sustainability and emission transparency.

This development presents a strategic opportunity: A consistently anchored circular economy is no longer a nice-to-have but a future-defining factor for the competitiveness of electronics companies. Collaboration with specialized partners like MTM Ruhrzinn can be the key - to intelligent resource use and a business model that is both ecologically responsible and economically viable.