Sustainability and expectations for packaging machinery construction

“It is time for a change”

At the Packaging Machinery Conference, representatives of the mechanical engineering industry were mainly on stage. But with Bernd Büsing, Head of Corporate Packaging at Nestlé Germany, a real user also had a say. And he spoke plainly about what he expects from suppliers to be able to package sustainably.

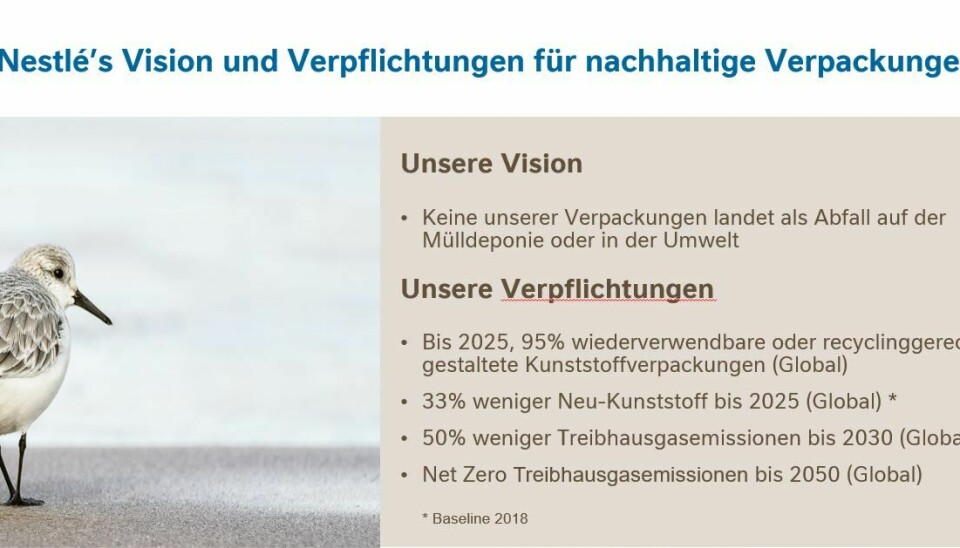

Büsing opened his presentation with Nestlé's vision: "None of our packaging should end up as waste in the environment or in a landfill." This goal presents an immense challenge, especially in regions like Southeast Asia, where the necessary waste management infrastructure is often lacking.

To still be able to realize this vision, Nestlé has set several concrete goals. A key point is the design of packaging for recyclability: "We have set a global goal to design more than 95 percent of our plastic packaging to be recyclable by 2025. We are working hard to achieve 100 percent," emphasized Büsing. The recyclability depends not only on the design but also on the available infrastructure. And this is currently still very heterogeneous. "That's why we are now focusing on the aspect we can directly influence, which is the recyclable design of our packaging," emphasized Büsing. By the end of 2023, 83.5% of Nestlé's plastic packaging worldwide was suitable for recycling or reusable.

Another significant goal is the reduction of the use of new plastic: "We have committed to using one-third less new plastic by 2025," explained Büsing. This scale is based on consumption figures from 2018. Furthermore, Nestlé aims to halve its greenhouse gas emissions by 2030 and achieve net zero emissions by 2050.

The packaging strategy is based on five pillars:

- Reduction of packaging material

- Scalable reuse and refill systems

- Improvement of packaging, especially in terms of recyclability

- Expansion of infrastructure for a waste-free future

- New behaviors in our own operations, with suppliers, in trade, and with consumers.

Reduction of packaging material

Nestlé has already taken various measures to reduce packaging material. One example is the reduction of wall thicknesses in Nescafé Dolce Gusto coffee capsules by 20%, which has already led to a saving of over 1,000 tons of plastic per year. In glass packaging, such as the Maggi seasoning bottle, 683 tons per year were saved through wall thickness reduction. "Plastic reduction can be achieved through classic reduction of wall thicknesses or through substitution," explained Büsing. An example of this is the switch of Smarties packaging to recyclable paper, saving 191 tons of plastic. This directly leads to the next point.

Substitution of packaging materials

An important strategy is the substitution of plastics with alternative materials such as paper - "paperization". Nestlé has already achieved initial successes here, as shown by the switch of Smarties packaging to recyclable paper. "Paper is a very exciting material," commented Büsing, while also emphasizing the challenges and inevitable learning curves in the transition. Another example is the switch of Maggi transport packaging from non-recyclable EPS trays to paper pulp trays, which led to significant plastic savings.

At this point, Büsing also had specific requests for the packaging machinery industry: "Building competence in paper processing should be a priority, for example, sealing within narrow temperature windows and gentle handling of packaging materials."

Use and processing of recyclates

The use of recycled materials is another central component of the strategy. Büsing emphasized the importance of recycled materials, particularly in transport packaging and shrink films. The switch from PP to PET for squeeze bottles is another example that illustrates the challenges and progress in the field of recycled materials.

Here too, Büsing had assignments for solution providers: "The machines must be able to quickly adapt to varying material properties to ensure consistent quality. Additionally, an 'electronic nose' that can identify potential contaminants would be beneficial."

Scaling of reusable and refill systems

Nestlé sees great potential in scaling reusable and refill systems to reduce the need for single-use packaging

to reduce. Büsing emphasized the need for sensible standardization and pool solutions to make these systems efficient. "We need sensible standardization and an open system for brands and products," he explained. An example last year was the company's pilot project in collaboration with the startup Circolution and their reusable solution "Anita in Steel," which was tested in selected supermarkets and produced promising results."We need solutions for 100% inline inspections here. Both to guarantee the necessary hygiene. But also for optical quality control, to be able to sort out reusable containers and send them for recycling if necessary. We also need smaller, decentralized filling and packaging plants to realize a comprehensive infrastructure and thus keep transport routes as short as possible."

Improved recyclability of packaging

The switch to recyclable materials and the improvement of packaging are essential to achieve sustainability goals. Büsing emphasized that 96% of Nestlé Germany's current packaging is already recyclable: "We still have four percent to go. And that's no surprise: flexible packaging is also a challenge here." Examples include the switch from PET-aluminum-PE bags to monomaterials like mono-OPP for Maggi soups and sauces. "Opportunities should be created here to retrofit existing packaging lines for processing D4R materials - while maintaining the machine efficiency achieved so far," demanded Büsing.

Cycle only in cooperation

At the end of his presentation, Büsing emphasized that machine manufacturers need to be proactive and collaborate with Nestlé to develop solutions. “Machine suppliers need to shift more into active rather than reactive mode,” he commented, highlighting the importance of collaboration along the entire value chain. “Cooperation is the key to success,” he stressed.

In this context, collaboration among suppliers, trade, competitors, NGOs, and not least governments plays a central role. “We need the right laws to create a level playing field,” Büsing explained, concluding his presentation with an urgent appeal: “The greatest danger is believing that someone else will save the world. It is time for change and transformation - and we all need to be part of it.”