IIoT solutions

Digital services for the mechanical engineering of tomorrow

Only those who actively shape the digital transformation can successfully master the upcoming challenges of the data age. Aerzen Digital Systems develops IIoT solutions for Aerzen machines as well as customer-specific process structures and supports companies in leveraging the potential of digitalization.

To keep up with technological progress and growing market demands, there is no way around digitalization. Nevertheless, it is still difficult for many companies to implement it successfully - even though they should know better. But why is realization lacking in many places?

Carsten Wendt, product manager at Aerzen Digital Systems, says: "The reasons are varied and range from a lack of know-how to security concerns to innovation-hostile structures and a lack of willingness to invest. Whatever the cause, one thing must be said clearly and distinctly: Those who do not digitalize will not be able to survive in the market in the long run." But how do companies make the leap out of their slumber and into the digital future? How do they bring about the necessary change and get their digitalization going?

Aerzen Digital Systems offers support. With innovative industrial IoT solutions and individual consulting services, the globally operating company is driving digital transformation forward and making mechanical engineering fit for the upcoming challenges - regardless of industry, technology, or application. Carsten Wendt emphasizes: "Digitalization is not an end in itself, but a profitable investment in the future. It primarily serves process optimization and is a tool to achieve added value or savings!"

Tailored digital solutions

Aerzen Digital Systems GmbH is a wholly-owned subsidiary of Aerzener Maschinenfabrik GmbH and, as a long-standing partner of plant operators and planners, knows the needs and requirements of the market precisely. Together with the customer, the IoT and consulting specialist develops digital products and services that make the operation of machines and plants more reliable, energy-efficient, and safer - whether they are Aerzen units or customer-specific process structures. "We are an international team of highly motivated employees who are passionate about digital solutions, enjoy challenging projects, and focus on what is essential.

As part of the Aerzen Group, we can draw on over 160 years of application experience in the market for high-performance blowers and compressors. We combine this know-how with customer-centric innovation methodology and agile software development to realize tailored solutions that help companies leverage the potential of digitalization," says Carsten Wendt, adding: "We also pass on our experience and expertise to other mechanical engineering companies as part of our consulting services. In doing so, we aim to contribute to a pragmatic and successful digital transformation of mechanical engineering."

Open IIoT platform for digital analysis and control

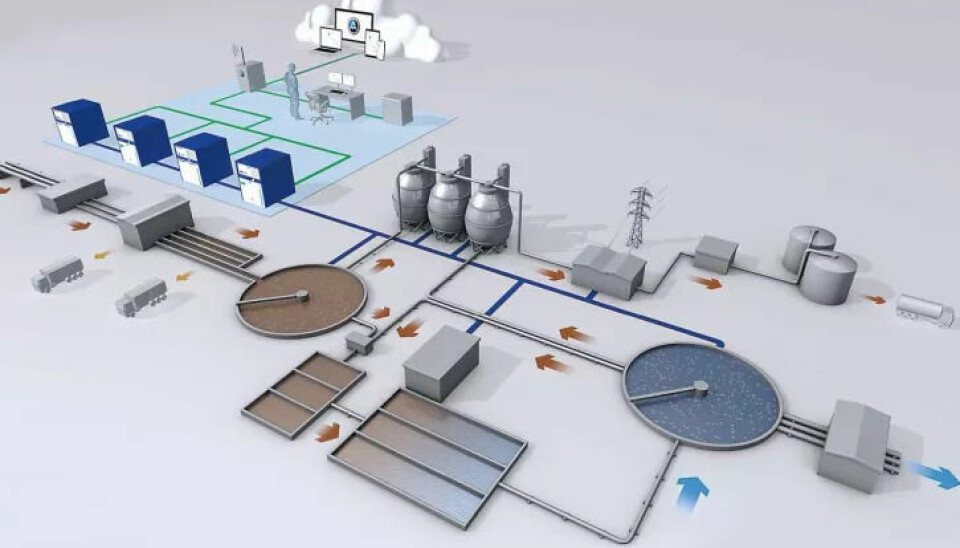

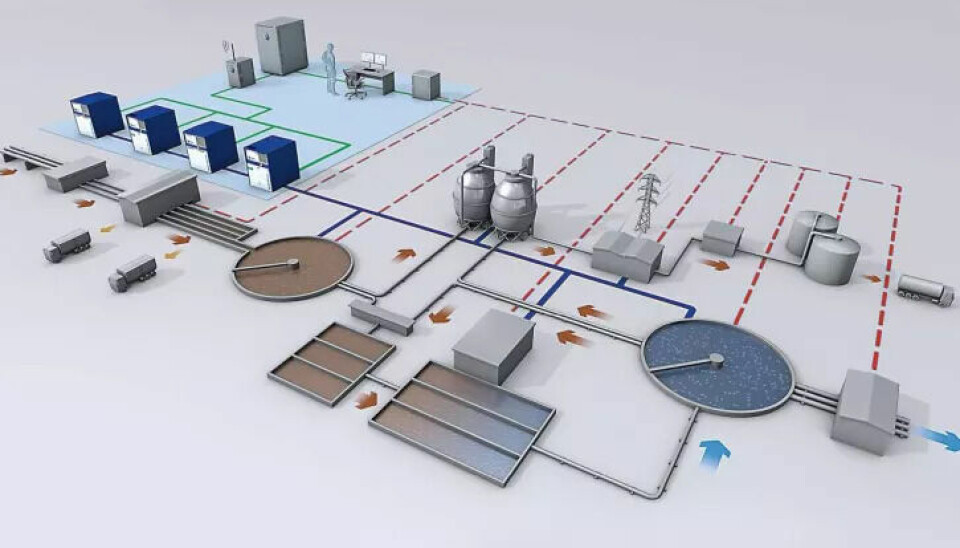

Whether it's global machine park management, improving machine and plant performance, increasing energy efficiency, enhancing availability, identifying savings potential, efficient composite control, smart maintenance, digital maintenance management, or process optimization: The solutions from Aerzen Digital Systems cover all requirements, processes, and areas, enabling simple, effective, and transparent machine, plant, and process management.

“Our IIoT platform for digital analysis and control is both hardware and controller independent. This is an absolute unique selling point,” emphasizes Carsten Wendt and explains: “The platform works with flexible end-to-end connections with all systems, devices, and controls - independent of manufacturer, brand, or provider, for individual machines and entire machine networks. We can connect all electronic communicative devices as field objects and also transfer data to third-party systems. Additionally, we are able to make customization adjustments of any kind and integrate individual functionalities.”

For customers, this means maximum flexibility and security. The individual modules of the innovative platform - asset management, system improvement, smart maintenance, system control, and data analytics services - are freely combinable and can be precisely tailored to the application-specific needs. Customers only book the services they actually need.

Modular functional diversity

The 'asset management' module is used for managing, monitoring, and optimizing processes, system states, as well as machine or system data, and provides a fundamental, clearly structured overview of the availability, productivity, and efficiency of the machine park in near real-time. It is indispensable for successful plant operation and forms the basis for all other modules.

The 'system improvement' module creates tailored transparency: with all relevant data, clearly visualized and intelligently processed. This allows unused efficiency and optimization potentials to be identified and exploited, improving the operation, reliability, and overall efficiency of the plant. The 'smart maintenance' module digitizes and standardizes the maintenance and repair process. It offers a uniform and central solution for the maintenance and service of all machines and electronic products in a plant - regardless of type and function. Features such as maintenance planners, maintenance checklists, and storage of all relevant documents facilitate work and support the management of maintenance measures. Proactive or predictive maintenance concepts are also feasible.

With the 'System Control' module, multiple identical or similar blowers and compressors can be optimally coordinated in a network using load balancing control to achieve the greatest possible energy efficiency - an important tool especially for wastewater treatment plants.

Focus on cybersecurity

A particularly sensitive issue in digitalization for many companies is cybersecurity. Aerzen Digital Systems therefore offers two operating models with almost identical functionality: cloud and local/on-prem. The cloud solution is a hosted platform operated at a decentralized location (data center). This offers advantages in terms of scalability and flexibility at lower entry costs.

With on-prem, all technology is installed and operated directly on-site in the customer's local network. This guarantees full control over data and security measures.

Speaking of security: with the European Union's NIS-2 directive for the protection of critical infrastructure, many small and medium-sized enterprises in sectors such as water, wastewater, energy, health, and telecommunications are expected to face new mandatory security measures and reporting obligations in March 2025. Among other things, affected companies may only use certain certified products, services, and services. The IIoT platform from Aerzen Digital has been developed and already certified according to IEC 62443. Thus, the platform is compliant with NIS2 and can be used in the corresponding critical areas.

Data-based services for all industries

Aerzen Digital Systems is the digitalization specialist within the Aerzen Group, but by no means limited to applications with process air and process gas. Quite the opposite. The range of solutions and services is open to all industrial applications and industries - whether it's wastewater treatment technology, drinking water supply, logistics, conveyor technology, food & beverage, cement production, maritime industry, or others.

"We are completely industry and application neutral. The functionalities of our open IIoT technology can be applied to all machines, technologies, and industrial applications. Through connectivity, we can integrate many communicative components. In close collaboration with operators and system integrators, we develop the appropriate digitalization strategy and support in all areas - from consulting through analysis, project planning, and development to commissioning and process optimization," explains Carsten Wendt and adds: "As a consulting partner, we also help machine builders to understand the potential of their machine data and translate it into practical solutions."

Digitalization: key success factor

Save electricity, improve performance, exploit efficiency potentials, increase availability, minimize operational risks, reduce complexity, avoid downtime, lower costs: Digitalization is the key to competitive processes, technological innovations, and new value creation models. It leads to more resource and cost efficiency, expands the range of possibilities, and ensures future viability.

As an experienced and competent partner, Aerzen Digital Systems accompanies companies from all industries on the path to digital ecosystems and makes a significant contribution to transparent, secure, and energy-efficient production and processing processes.

Advertisement “The future is digital. Together with the customer, we shape the change. We support on an equal footing and make companies strong for future challenges. Pragmatic, practice-oriented, and manufacturer-independent,” emphasizes Carsten Wendt.