Factory of the year: Outstanding digitalization

Mercedes: Flexibility and digitalization are in focus

The Mercedes-Benz plant in Rastatt impresses with flexible production and outstanding digitalization. But how did the team manage to maintain high-level production during a twelve-week renovation? The answer is here.

Whether combustion engine, hybrid, or electric - vehicle production at the Mercedes-Benz plant in Rastatt is very flexible and can respond to any demand fluctuations and model adjustments. But that alone does not distinguish the Factory of the Year winner in the category 'Outstanding Digitalization'. "Our plant and our team are also very flexible," says site manager Marco Zwick, referring to the 2023 hall renovation. "Because one assembly hall was closed during the twelve-week renovation, we started three-shift operations in another assembly hall. This allowed us to maintain our output at a high level," Zwick praises the commitment of the employees.

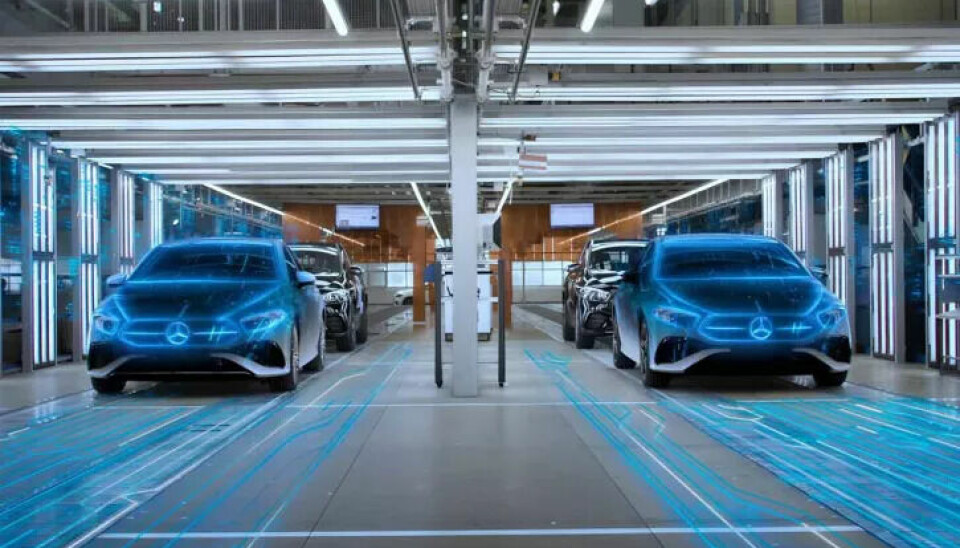

In preparation for the production of the new CLA as the first model on the Mercedes Modular Architecture (MMA), the winning plant in the Factory of the Year virtually represented and commissioned the renovation of an existing assembly hall for the first time in advance. For this purpose, all data of individual production facilities were digitally recorded and planned, tested, and adjusted accordingly in the virtual space.

The exact position of robots, supply routes, and production lines was simulated on the computer in advance, without interrupting the production of the current compact models A- and B-Class, GLA, and EQA. More than 400 kilometers of cable were laid to install the six new assembly lines and 240 new lifting hangers.

Assembly hall could be completely digitally planned

“Compared to a new building, a renovation always has the difference that you are bound by the shell of the building. Therefore, we have already chosen innovative approaches in the shell construction to achieve a densification to be able to represent the additional content that the new car brings,” says Zwick. He further explains: “Subsequently, we digitized all interfaces in this hall.” Starting with, for example, the conveyor technology that drives the vehicle into the filling system, up to the material supply to the line. All of this was digitally mapped to create the basis for the hall renovation.

“Then the new vehicle with the new geometry, the new processes, the new handling devices, and the new material provisions were integrated. This enabled us to completely digitally plan our assembly hall anew. In this way, we digitally identified possible inconsistencies in advance, which would otherwise have only become apparent in the hardware - for example, collisions in the conveyor technology. As a result, we were able to achieve not only much better quality in planning but also save a lot of time. With the digital twin, we have embarked on completely new paths, with which we were very successful,” the site manager is pleased.

Kearney saw it the same way and rated the factory of the year not only for its flexibility in production but also for the consistent application of the digital twin and digitalization as an essential part of increasing productivity, agility, and speed as extremely positive.

The basis for the 'Outstanding Digitalization' is the digital ecosystem MO360. Zwick explains: “We use this platform for the democratization of data worldwide across all plants. Among other things, we can retrieve all information on quality and production live.”

The jury was also impressed by AI applications

Numerous AI applications, which also impressed the jury, are based on this ecosystem, which is also the heart of the digital shop floor and performance management. One of them is the optimized process control in the paint shop. Previously, a combination of standard control and empirical values was used to keep parameters such as humidity and temperature constant during painting and to ensure downward airflow.

“Our approach was to develop a new program using artificial intelligence based on the existing data that provides us with the information for the ideal process. We found that airflow controls change because the AI can continuously react and readjust. This led to a 20 percent energy saving,” explains Zwick.

The rework assist is also based on AI. It is used to find the cause of error messages. Zwick explains: "If problems occur, the AI shows our employees approaches that lead to the best solution in 90 percent of cases. This way, we often reach our goal much faster. We have also developed several chatbots using AI that help the team easily find out certain facts without having to program Excels or macros, for example." In addition, AI is also used in Rastatt for energy consumption optimization.

An important factor at Mercedes: new technologies

In addition to digitization, the development of new technologies is on the list of success factors for Mercedes-Benz. Some of these were realized in collaboration with suppliers, such as seam sealing with drop-on-demand. To cover a sheet metal pairing with a seam, a PVC seam is applied with a nozzle in the conventional process. "When the seam comes together from three directions, you have a junction that you have to manually smooth out," Zwick explains the problem with this process.

To avoid this rework, a pilot was started in Rastatt where the nozzle is controlled by many individual nozzles. This allows the thickness and width of the seam to be controlled and ultimately the height of the junctions to be adjusted to the rest of the seam. This process, which is critical in terms of corrosion, is more stable and can be better monitored thanks to this innovation.

In addition, it is more material-efficient and therefore more sustainable. These two characteristics also shape the shell construction, where the Mercedes-Benz plant in Rastatt relies on the reuse of production equipment for at least two model cycles.

Transformation: Employees are involved

Overall, Mercedes-Benz was able to impress in the benchmark competition with numerous innovative approaches, many of which have already been realized.

“The jury's verdict naturally confirms our strategy. A key factor is that we involve our employees to drive the transformation forward. The integration of the entire team is very important to me, which is why they were involved in all the topics and projects we have successfully implemented and are part of the solutions. That was the great success factor,” emphasizes Zwick.